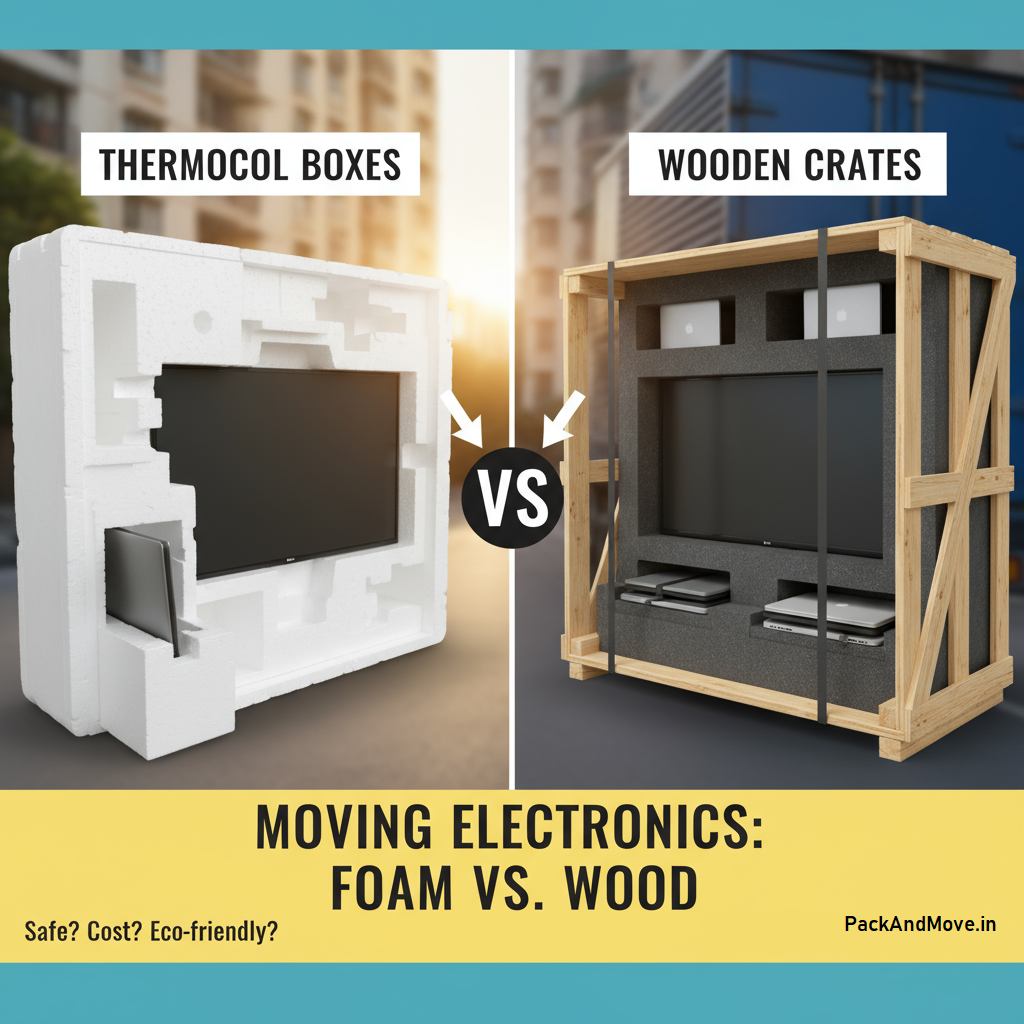

Thermocol Boxes vs Wooden Crates for Electronics Packing during House/Office Shifting in India

When it comes to packing electronics for house or office shifting in India, the choice between thermocol boxes and wooden crates can make all the difference in ensuring your valuable devices arrive safely. Electronics such as televisions, laptops, desktop computers, servers, refrigerators, and other appliances are delicate items that require careful handling to prevent damage from shocks, vibrations, moisture, and static electricity during transit. In a country like India, where roads can be uneven, weather conditions vary dramatically, and moving distances range from short urban relocations to long inter-state journeys, selecting the right packing material is crucial for a stress-free experience.

Thermocol boxes, made from expanded polystyrene foam, are popular for their lightweight nature and excellent cushioning properties, making them a go-to option for budget-conscious movers handling local shifts. On the other hand, wooden crates, constructed from sturdy timber or plywood, offer robust protection that is ideal for heavier items and longer distances, providing a secure enclosure that can withstand rough handling by loaders and transporters. This comprehensive guide from PackAndMove.in dives deep into the pros and cons of each, helping you make an informed decision based on your specific shifting needs, whether you're moving a small apartment in Mumbai or an entire office setup from Delhi to Bangalore.

Understanding the nuances of these packing solutions is especially important in India, where monsoon seasons bring heavy rains, summer heat can reach extreme levels, and the logistics industry often involves multiple handling points. By the end of this article, you'll have a clear framework to choose the best option, along with practical tips to pack your electronics securely and minimize risks. Whether you're a homeowner planning a DIY move or a business owner coordinating an office relocation, these insights will save you time, money, and potential headaches.

Understanding Thermocol Boxes

Thermocol, commonly known as expanded polystyrene (EPS) in technical terms, is a versatile packaging material that has been a staple in India's moving industry for decades due to its affordability and effectiveness in protecting fragile items. It is produced by expanding polystyrene beads with steam, creating a lightweight foam that traps air in tiny closed cells, giving it superior insulation and shock-absorbing qualities. For electronics packing, thermocol boxes are typically molded into custom shapes that fit specific devices, such as TV screens or computer monitors, ensuring a snug fit that minimizes movement during transit.

The primary appeal of thermocol lies in its density variations, which range from low-density (around 10-15 kg/m³) for general cushioning to higher-density (20-40 kg/m³) options for more robust protection against impacts. In the context of Indian house shifts, where trucks often navigate crowded city streets and pothole-filled roads, this density helps absorb vibrations that could otherwise crack delicate components like LCD panels or hard drives. For instance, when packing a laptop, a thermocol insert can cradle the device perfectly, preventing it from shifting inside a larger carton and reducing the risk of screen damage or keyboard misalignment.

One of the standout features of thermocol is its thermal insulation properties, which are particularly beneficial during India's diverse climate conditions. In scorching summers, it keeps heat-sensitive electronics like batteries and processors from overheating in non-air-conditioned vehicles. Conversely, its non-absorbent nature makes it resistant to minor moisture exposure, unlike cardboard that can warp or weaken when damp. This is a big plus for moves during the pre-monsoon period in cities like Kolkata or Chennai, where humidity levels soar.

However, thermocol isn't without its challenges, especially when it comes to static electricity. Standard thermocol can generate static charges through friction during packing or unpacking, which poses a significant risk to sensitive electronic circuits, potentially causing short circuits or data corruption in devices like hard drives or RAM modules. To mitigate this, many professional packers recommend using anti-static thermocol variants or adding conductive liners inside the boxes. In office shifting scenarios, where multiple servers and networking equipment are involved, this precaution is non-negotiable to avoid costly downtime post-move.

From a cost perspective, thermocol boxes are incredibly economical, often costing just a fraction of other materials, which makes them ideal for students, small families, or budget relocations. You can source them from local packaging suppliers in markets like Delhi's Sadar Bazaar or Mumbai's Crawford Market, where prices start as low as ₹300 for a standard box. Custom molding services are also widely available, allowing you to get tailored fits for odd-shaped items like gaming consoles or home theater systems without breaking the bank.

Despite these advantages, thermocol has limitations in terms of durability against punctures and heavy stacking. In multi-story apartment buildings common in Indian metros, where elevators might be unavailable and items are carried up stairs, thermocol can crack under point pressure from sharp edges or heavy loads above. For such cases, it's often best used as an inner liner within a stronger outer box, like a double-wall corrugated carton, to enhance overall strength. Additionally, environmental concerns are rising, as thermocol is not biodegradable and contributes to plastic waste; under India's Plastic Waste Management Rules, responsible disposal or recycling through certified centers is encouraged to promote sustainability in moving practices.

In summary, thermocol boxes shine in scenarios requiring lightweight, cost-effective cushioning for short-distance moves with minimal handling, but they demand careful selection of density and anti-static features to fully protect electronics. For households shifting within the same city, like from one neighborhood in Pune to another, thermocol provides a practical solution that balances protection and ease of use.

Exploring Wooden Crates

Wooden crates represent the gold standard in heavy-duty packing for electronics, offering a level of structural integrity that thermocol simply can't match, especially for long-distance or high-value relocations in India. These crates are typically crafted from high-quality plywood, pine, or hardwood panels, assembled with nails, screws, or metal straps to create a rigid, tamper-resistant enclosure capable of withstanding the rigors of professional transport. In the Indian context, where goods often travel via shared trucks with multiple stops, wooden crates prevent crushing from stacked loads and protect against unauthorized access during transit.

The construction of a wooden crate allows for extensive customization, including internal dividers, foam padding, and bracing struts that immobilize electronics completely. For example, when packing a large LED television or an office projector, packers can add corner reinforcements and shock-absorbing mounts to distribute weight evenly, ensuring the item remains stable even on bumpy national highways like the Mumbai-Pune Expressway. This level of engineering is why wooden crates are preferred for corporate office shifts, where downtime from damaged IT equipment can cost thousands in lost productivity.

Unlike thermocol, wooden crates pose no static electricity risks, as wood is a natural insulator that doesn't generate charges. This makes them inherently safer for sensitive devices like medical electronics or data centers being relocated from Bangalore to Hyderabad. To address moisture concerns—prevalent during India's monsoon from June to September—professional crates incorporate plastic vapor barriers, silica gel packets, and ventilation holes to maintain internal dryness, preventing mold or corrosion on circuit boards and connectors.

In terms of compliance, domestic wooden crates in India do not require the international ISPM 15 heat treatment for phytosanitary standards, which simplifies sourcing from local manufacturers in industrial hubs like Jalandhar or Ghaziabad. However, opting for treated or laminated wood ensures longevity and resistance to pests, which is vital for reusable crates that can be employed in multiple moves. PackAndMove.in partners often provide these crates as part of full-service packages, complete with labeling and insurance integration for added peace of mind.

Cost-wise, wooden crates are a higher investment, ranging from ₹1,800 for small units to over ₹22,000 for large custom builds, but their durability justifies the expense for items valued above ₹10,000. The added weight—often 10-30 kg per crate—can increase transportation fees by 10-20%, particularly for air or express road services, but this is offset by reduced damage claims and the ability to reuse them up to 8 times with minor repairs. For eco-friendly moves, sustainable sourcing from certified timber suppliers aligns with India's growing emphasis on green logistics.

Handling wooden crates requires more effort due to their bulk and weight, which can be challenging in narrow Indian stairwells or congested loading areas. Yet, their stackability optimizes truck space, allowing more items per vehicle and potentially lowering overall shipping costs for bulk office relocations. In coastal cities like Chennai or Kochi, where humidity is a constant threat, reinforced wooden crates with desiccants provide superior protection compared to lighter alternatives, ensuring electronics remain operational upon arrival.

Overall, wooden crates are the choice for scenarios demanding maximum protection, such as inter-city office migrations or packing high-end home entertainment systems, where the investment in security translates to long-term savings and reliability.

Key Comparison Factors

Protection and Durability

Protection is the cornerstone of any electronics packing strategy, and here wooden crates clearly edge out thermocol in durability for demanding Indian shifts. Wooden structures can absorb and distribute impacts from drops or collisions far better, with tests showing they handle up to 50% more force on routes exceeding 500 km, where items face repeated handlings at toll plazas and warehouses. Thermocol, while excellent for minor vibrations like those in city traffic, can compress or shatter under concentrated pressure, such as when a heavy box lands on a corner during unloading in a busy Delhi market.

For electrostatic discharge (ESD) safety, both materials require supplementary measures, but wooden crates offer a neutral base that integrates seamlessly with anti-static foams or bags, eliminating movement that could cause friction-induced charges. In office environments with servers or networking gear, this stability prevents micro-vibrations from loosening connections, a common issue in thermocol where slight shifts might occur over long hauls. Real-world examples from moves in Rajasthan's arid terrains highlight how wooden bracing maintains alignment for optical drives and screens, reducing failure rates by up to 70%.

Durability also extends to stacking; wooden crates support vertical loads without deformation, ideal for multi-tier truck arrangements, whereas thermocol needs additional outer reinforcements to avoid collapse in similar setups. This factor is critical for apartment dwellers in high-rises, where space constraints during loading amplify stacking needs.

Moisture and Climate Suitability

India's tropical climate, with its monsoons, high humidity, and temperature swings, demands packing that combats moisture ingress, and wooden crates with proper treatments outperform thermocol in severe conditions. Equipped with liners and desiccants, crates create a sealed microenvironment that keeps relative humidity below 40%, safeguarding against condensation on cold electronics like air conditioners during rainy season transports from Kerala to Tamil Nadu.

Thermocol's inherent water-repellency handles splashes or light drizzle effectively, as it doesn't absorb moisture like paper-based materials, making it suitable for dry interiors or short urban moves. However, prolonged exposure, such as in flooded loading zones during Mumbai's heavy rains, can cause it to soften or disintegrate, unlike treated wood that maintains integrity. In hot, dry areas like Ahmedabad, thermocol's insulation prevents thermal runaway in lithium-ion batteries, but crates with ventilation manage airflow better for bulkier appliances.

For air-conditioned office shifts versus open trucks, thermocol suffices in controlled environments, but wooden options excel in variable conditions, ensuring consistent protection across India's diverse regions from Himalayan foothills to coastal plains.

Weight, Cost, and Handling

Weight is a decisive factor in Indian logistics, where fuel costs and labor rates vary; thermocol's featherlight profile (70-80% lighter than wood) simplifies DIY handling for house moves, reducing strain on movers climbing multiple flights in buildings without lifts. This lightness also trims transport surcharges on short routes, making it a favorite for students relocating hostels in cities like Lucknow or Jaipur.

Weight, Cost, and Handling

Thermocol boxes weigh 70-80% less than equivalent wooden ones, easing labor for DIY house moves and cutting fuel surcharges on short hauls. Costs range from ₹300-₹4,500 for thermocol versus ₹1,800-₹22,000 for crates, making thermocol budget-friendly for students or small offices. Wooden options add ₹500-₹2,000 in transport fees but reduce damage claims, potentially saving ₹5,000+ on repairs for a single server.

| Factor |

Thermocol Boxes |

Wooden Crates |

| Shock Absorption |

Basic (density-dependent) |

High (structural bracing) |

| ESD Safety |

Requires anti-static add-ons |

Neutral; pairs with any inner |

| Moisture Resistance |

Good (non-absorbent) |

Needs liners; excellent with prep |

| Weight (per unit) |

1-5 kg |

10-30 kg |

| Cost Range (₹) |

300-4,500 |

1,800-22,000 |

| Best for Distance |

<500 km local |

>500 km intercity |

| Reusability |

Low (single-use often) |

High (3-8 cycles) |

Cost comparisons reveal thermocol's edge for low-budget scenarios, with prices 60-80% lower, allowing allocation of savings to other moving expenses like insurance. Wooden crates, though pricier upfront, yield returns through reusability and damage prevention; for a ₹50,000 server, avoiding a ₹5,000 repair bill more than covers the premium. Handling-wise, thermocol's flexibility aids quick packing in time-crunched scenarios, while wooden crates demand tools and manpower but offer forklift compatibility for efficient warehouse loading in industrial shifts.

In essence, balance these elements based on your move's scale: thermocol for economical ease, wood for premium assurance.

Decision Framework for Indian Shifts

Navigating the decision between thermocol and wooden crates starts with evaluating your shift's specifics: distance, item value, and environmental risks. For local house relocations under 100 km, like within Gurgaon or Noida, thermocol boxes encased in sturdy cartons provide sufficient cushioning for everyday electronics such as microwaves or sound systems, keeping costs under control while ensuring basic safety.

For longer journeys over 700 km, such as from Kolkata to Chennai, or office relocations involving critical infrastructure, wooden crates are indispensable, incorporating shock indicators and GPS tracking for real-time monitoring. During monsoons, prioritize crates with enhanced sealing; in dry seasons, thermocol's insulation takes precedence. Hybrid methods, combining thermocol inserts within wooden frames, offer a middle ground for mixed loads, optimizing weight and protection for comprehensive moves.

Consider value thresholds: items under ₹5,000 can use thermocol, but higher-end gear warrants crates to mitigate total loss risks. Eco-aspects favor reusable wood, with thermocol recycling via urban collection drives. Always consult PackAndMove.in's verified professionals for site assessments, ensuring tailored solutions that align with your timeline and budget.

Route analysis is key—paved expressways suit both, but rural paths demand wooden durability. For international-standard offices, crates ensure compliance with ISO packing norms, while households benefit from thermocol's simplicity in unpackaging.

Packing Tips for Electronics

Effective packing begins with preparation: inventory your electronics, disassemble where possible (remove detachable parts like keyboards or stands), and clean surfaces to prevent dust accumulation during transit. Wrap individual components in anti-static bubble wrap or foam sheets before placing them into your chosen container, ensuring no metal parts touch to avoid scratches.

For thermocol, select densities above 20 kg/m³ for better resilience, fill all voids with crumpled paper or additional foam peanuts, and seal edges with strong packing tape to maintain shape. In wooden crates, use plywood dividers for separation, add desiccant packs for humidity control, and secure lids with screws for reusability. Test the setup by gently shaking to confirm immobility, simulating road bumps.

Loading strategies matter: place heavy crates at the truck's base for stability, position lighter thermocol packs higher but secured with ratchet straps to prevent sliding. Label everything clearly—"This Side Up," "Fragile," "Electronics"—and keep a manifest for quick unpacking. Post-move, acclimate items to room temperature before powering on to avoid condensation shocks.

Advanced tips include using corner protectors for screens, inventory photos for insurance, and professional valuation for high-value items. For bulk office packs, employ palletizing to streamline handling. With these steps, your electronics shift seamlessly via PackAndMove.in's network, covering metros to tier-2 cities.

For personalized guidance, connect with our packers in Delhi, Mumbai, Bangalore, or beyond. Safe packing paves the way for smooth transitions—choose based on your unique needs for a worry-free move.